A Peanut Butter Cup Porter

Having attempted and failed at brewing an IPA, I decided to try another new style for me – one that I actually like to drink: a peanut butter porter. I did my research on how to approach this style. My buddy had also once attempted a butter-based beer and relayed his frustrations; adding oils to beer will simply create a oily mess. Oils and fats do not play well with foam; but if you are looking for a flat, head-less beer, feel free to proceed without abandon.

However, learning from his experience with almond butter, I read up on using powdered peanut butter, PB2. The beer forums suggested adding it at the end of the boil or in a secondary fermentation vessel. Not quite sure if I would be inadvertently introducing foreign microbes when adding without first sanitizing, I opted for the former: adding the PB2 near the end of the boil.

| Grain | Amount |

|---|---|

| Pale Ale | 1.75 lbs |

| CaraPils | 5.5 oz |

| CaraBelge | 2.8 oz |

| Carafa | 2.8 oz |

| Special W | 1.5 oz |

| Hop | Amount | Time |

|---|---|---|

| Fuggles | 0.2 oz | 60 min |

| Tettnang | 0.2 oz | 20 min |

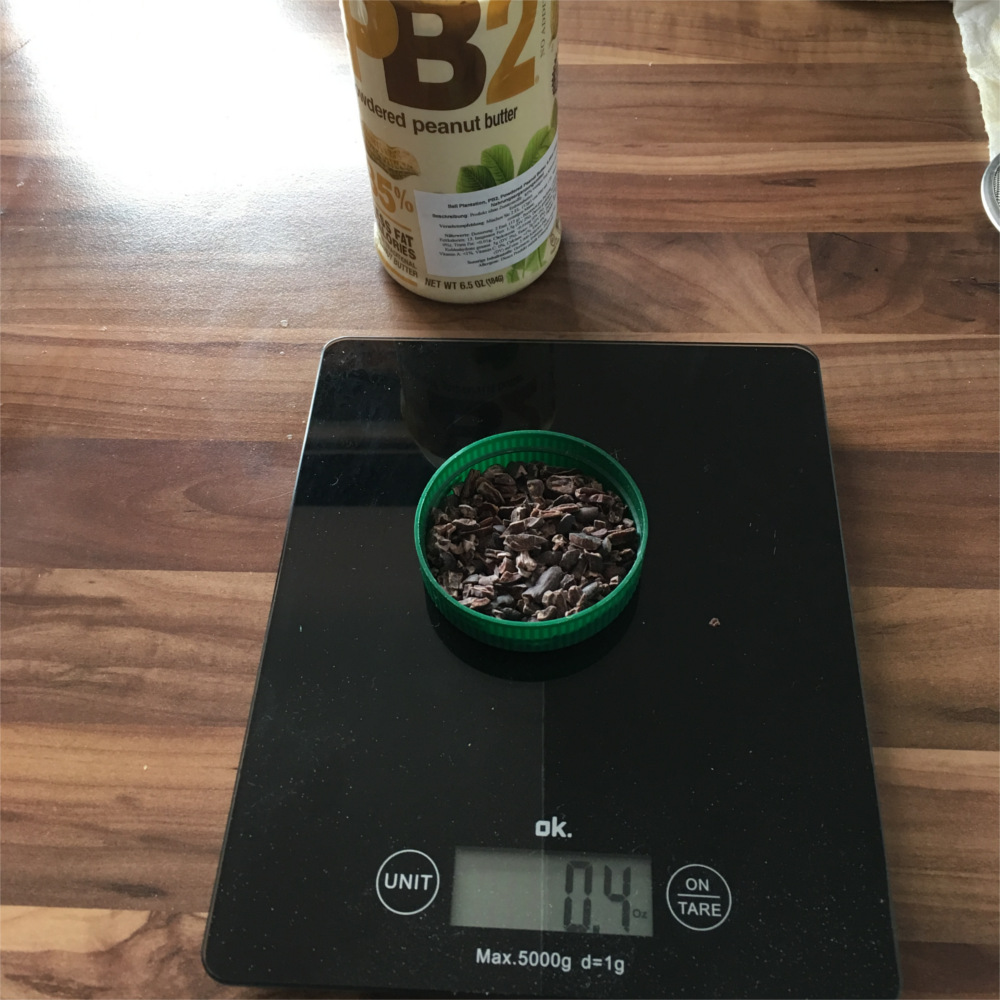

As this was to be a peanut butter cup porter, I prepared the PB2 and the chocolate additives. For my one gallon (or four liter) batch, the recipes suggested adding 6.5 oz of PB2, which was the entire contents of the canister; this was added with 10 minutes left in the boil. In addition to this powder, I added 0.4 oz of CocoaNibs, added at flame out (i.e., at the end of the boil when I turned off the burner). My brew log consisted of the following:

As this was to be a peanut butter cup porter, I prepared the PB2 and the chocolate additives. For my one gallon (or four liter) batch, the recipes suggested adding 6.5 oz of PB2, which was the entire contents of the canister; this was added with 10 minutes left in the boil. In addition to this powder, I added 0.4 oz of CocoaNibs, added at flame out (i.e., at the end of the boil when I turned off the burner). My brew log consisted of the following:

| Time | Activity |

|---|---|

| 11:55 | Dough in water at 70°F ~ 3 L with grains |

| 12:10 | Added 1.25 L boiling water – heat until 122°F is reached |

| 12:18 | 122°F – 4.5 L total with grains |

| 12:48 | Turned on burner |

| 12:55 | 157°F |

| 13:02 | 154°F – Desired beta rest temperature |

| 13:45 | Turned on burner |

| 13:50 | 164°F – Alpha rest |

| 14:05 | Turned on burner |

| 14:15 | 174°F – Mash out |

| 14:25 | Start Sparge |

| 14:40 | Sparge End – Go to Boil |

| 14:42 | Boil Begins – Add first hops |

| 15:22 | Add add’l hops |

| 15:32 | Add PB2 |

| 15:42 | Boil Ends – Add CocoaNibs – whirlpool |

| 16:00 | Stopped whirlpool – put in freezer ~ 3 L |

| 20:00 | Racked to carboy – added much water |

| 18:00 (+14 Days) | Bottled with 0.7 oz sugar |

While filtering and transferring from my boiling pot to the carboy, I discovered that the bottom half of my stock pot was a very thick, gelatinous butter. I cannot describe the frustration of trying to “squeeze” as much liquid out of the pot and into the carboy as possible. I ended up, in desperation, letting the filter lay out over night and adding to the carboy the additional liquid that drained from it. Even with that scavenged liquid, most of the carboy was extra water added in order to hit four liters.

I used a generic beer yeast called “London Ale Yeast”. I added too much as the fermentation process went too fast and pushed foam out through the airlock. It was a small mess and did not end up contaminating the batch.

The final product was extremely thin. The alcohol content was where I would expect it, but the peanut butter flavor was too subtle for my liking. In fact, all flavor was too subtle. In my next attempt, I will be transferring the entire contents of the stock pot to the carboy without filtering in hopes of a more pronounced peanut butter flavor. My hypothesis is that this may simply push the frustration to bottling.

Verdict: unsuccessful