The Goat Creamery Internship – Round Two

With the end of the baking academy and the decision to not continue on at the bakery, I found myself without a plan. In order to remain in the country, one is required. As my current visa was granted for voluntary internships, I set about getting some lined up. The problem was the summer vacations made it hard to get in contact with the owners of various businesses. And then there were conflicts from the start of the new apprentices, whose contracts begin each year on August 1. Luckily, my goat cheese internship from 2018 agreed to let me hang out for a couple weeks at the end of July.

Not too much had changed since the past summer: they were still milking about 90 goats and making the same assortment of cheeses. However, the cheddar that I made the previous summer was somewhat of a hit. I was gifted one of the last packages. I was honored to see that the packaging touted an “original American recipe” – yup, that was from this Wisconsinite.

The creamery did have a new worker, who was pleasant to work with. However, now there were three ladies in the creamery and eight times the gossip. I do not play sides, but I got to hear everyone’s perspective on the qualities lacking in the other coworkers. It makes one’s head spin. On the plus side, the farmstead had an intern for the summer: a nice young lady from Austria. She was difficult to understand given her accent. But, she was not afraid to sing along to the radio with me.

In talking with the owner, we worked through some ideas to step up our Cheddar-game. I had had some success in soaking the curd in dark beer or red wine in order to ‘stain’ the outside of the curd before pressing. After pressed, the cheese gained a marbling effect. She liked the idea, but not the alcohol. We landed on pulverizing cornflower petals and dusting the curds with that during salting.

Our first week’s trial had much of our color running away with the whey that was being expelled during salting. As a result, we did not see much of the blue color left in the cheese. We needed a new plan for the next week’s batch.

As the salt expelled so much whey, I opted in the second week to apply the salt and then add the cornflower petals. It was still not perfect, but one could see that the color remained in the final wheels.

Once again, I was afforded the opportunity to make my own goat Gouda – from pasteurization to clean up. The owner was around as a safety net, but there is always a feeling of accomplishment when all the equipment is at one’s disposal and any fault in the resulting cheese is solely yours. Look out for batch #30. My batch #25 from 2018 was fine enough to be selected for longer ripening; it is being sold this year as ‘aged Gouda’. Hopefully #30 will have the same fate next year.

The owner had some blue cheese mold that she wanted to use, so we attempted to make a blue cheese with the goat milk. She wanted a natural rind so added some white mold cultures that are generally used for the Camembert. I was afterwards responsible for stabbing the wheels repeatedly and daily in order to bring oxygen to the centers for the blue mold to flourish. Unfortunately, the white mold was too aggressive and continually closed up the holes. This experiment was unsuccessful.

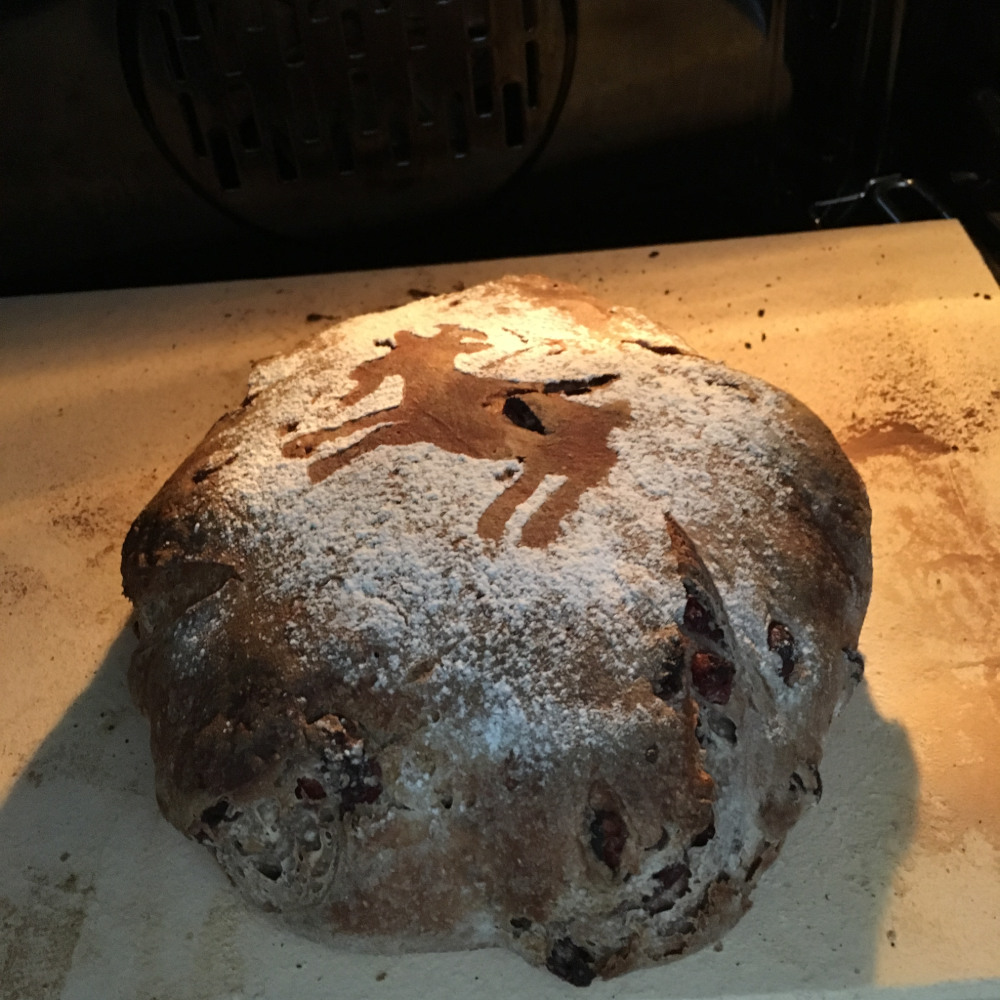

As a thank you for the short-notice internship, I borrowed some of their whey and gifted them back cranberry sourdough (with walnuts) bread with their logo design on top. As I was experimenting with using wholegrain rye instead of refined version, the loaf was not spectacular, but the taste was spot on.

I hope that this earns me a spot back on the farmstead next year.