Dill Cream Cheese

In Germany, “Frischkäse” is an umbrella term that encompasses a variety of cheese types from Quark to Ricotta to Mascarpone to Cream Cheese and even Cottage Cheese. It is not always clear what you are buying with that label. As I had recently acquired some rennet and some calcium chloride, I decided to make my own cream cheese… and I love dill, so I threw that in, too.

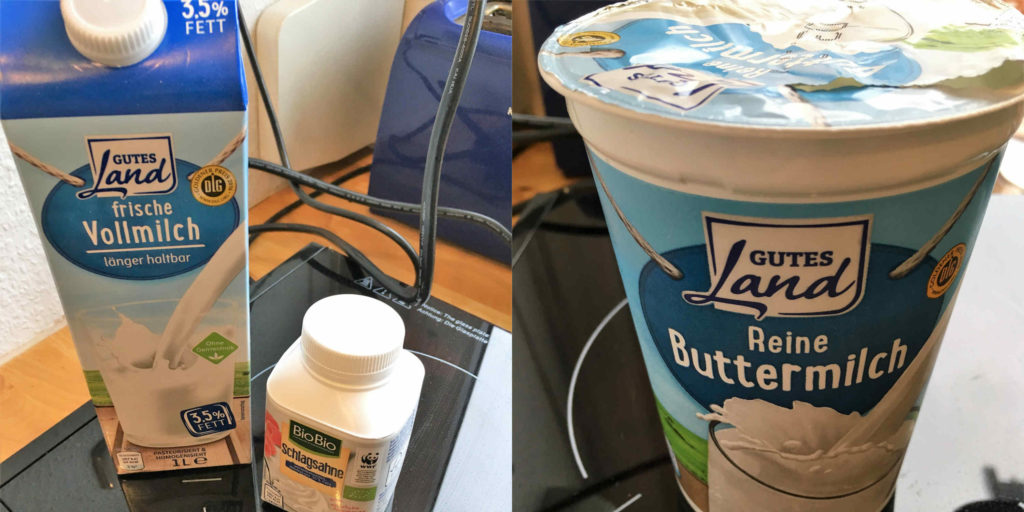

For anyone making cheese at home without access to raw milk, you will want to use some calcium chloride to reintroduce ions lost during the pasteurization process.“For anyone making cheese at home without access to raw milk, you will want to use some calcium chloride.” While I have found some sources of raw milk here in Germany, I do not have access to a vehicle to get it on a regular basis. So, I simply picked up some milk from the local grocery store. I purchase the milk that is refrigerated (pasteurized), not the unrefrigerated milk, which is ultra-pasteurized. The latter has no hope of becoming cheese, as too much has been destroyed in that process.

I was looking to make a small amount of cream cheese to last me a couple weeks, so I have used a liter of whole milk (between 3.5 and 4 percent milk fat) and enough heavy cream (minimum 35 percent milk fat) to get my total milk fat content between 10 and 20 percent. I also had some buttermilk on hand as this already has beneficial live cultures that I will need to make and maintain my cream cheese.

I warmed the milk and heavy cream mixture to a temperature that was warm to the touch (somewhere around 80°F) and added a tablespoon or so of buttermilk. After considering it well-mixed, I added only a couple drops of calcium chloride. After further stirring, I added a bit of rennet, mixed, and stopped all milk motion. The measurements do not need to be exact as I am not aging the cheese and will not likely suffer the consequence of over-rennetting. Regardless, you probably only need less than one-fourth teaspoon of rennet for so little milk. I put the warm pot in a warm place for about 12 hours. I was not able to maintain a consistent temperature, which would have been beneficial to the final product.

While I boiled some water, I cut the curd mass into one-inch cubes. I put a good amount of dill in the boiling water to kill any bacteria that may be living on the dried herb. When the dill-water cooled to about 170°F, I mixed the two with the hope of getting the mixture’s temperature to approximately 125°F in order to kill the culture added from the buttermilk (i.e., stop it from its acid production). I personally had to transfer the curd and the dill-water to another bowl due to size limitations of the pot; generally, you should add the water directly to the pot while carefully stirring.

After thoroughly warmed, I transferred the contents to a cheesecloth-lined colander to drain overnight. The final consistency will be more grainy than you would find in store-bought product as there are no additives to produce a smooth texture. I did add some additional heavy cream at the end in order to make it more spreadable. Also, I added some salt to taste. This cream cheese was delicious and can be completed from start-to-finish in 24 hours. Know that this “fresh cheese” should be consumed within ten days, which is generally not problematic for me.